Contract Packaging & Assembly Services in Indiana

Outsource your assembly and packaging to an experienced partner. Based in Indiana, XPress360 helps brands streamline production from box to shelf.

Your Product, Packaged for Success

With over 30 years of experience, XPress360 has developed a full suite of packaging and assembly services to support brands of every size. Whether you need kitting, shrink wrapping, or hand assembly, our Indiana-based team is ready to streamline your operations and help you scale faster.

Shrink Wrapping

Kitting Services

Labeling / Relabeling

Display Assembly

Belly Banding

Fulfillment

Services

Subscription

Box Packaging

Hand Assembly

Repackaging

Services

Co-packing

Services

Shrink wrapping is one of the best ways to seal and protect your retail package while giving it a polished, upscale look. At XPress360, based in Indianapolis, we bring over 20 years of experience in shrink wrapping retail products and multipacks with speed, precision, and consistency.

Our Indiana facility is equipped with a full range of machinery—manual L-Bar, semi-automatic, and fully automatic systems—so we can handle projects of any size and volume for businesses throughout cities like Carmel, Plainfield, and Brownsburg. We use only high-clarity, premium-grade film to ensure a clean, crisp finish and provide quick turnaround, often beginning production within 24 hours of receiving your materials.

In 2015, we expanded our capabilities by adding tray wrapping and polyethylene film bundling equipment from Arpac, a leader in shrink technology. This lets us maintain high daily production rates with minimal downtime and multiple shift flexibility.

Poly bundling is ideal for heavier items—like glass, jars, or food and beverage packs—and is known for its durability, stackability, and cost-efficiency in shipping and handling. Our team is trained to optimize packaging for strength, presentation, and supply chain efficiency.

Kitting is the process of grouping multiple components into ready-to-ship sets or units, and it plays a crucial role in both fulfillment speed and cost-efficiency. At XPress360 in Indianapolis, we provide scalable, customizable kitting and assembly services tailored to each client’s operational needs across Indiana, from Columbus to Greenfield.

We can support a single element of your workflow or deliver full turnkey kitting, managing everything from printing and packaging component sourcing to final assembly and shipment. Our operations team applies best practices for layout, task assignment, materials handling, and shipping to ensure accuracy and efficiency at every stage.

Whether you require cell-based, line-based, or hybrid kitting methods, we integrate hand work, automation, and QA protocols to match your complexity. From receiving through final distribution, we design the process around your budget and timeline—without sacrificing quality.

Our value lies in consistency, flexibility, and the ability to handle even the most custom or high-volume kitting jobs with speed and precision.

XPress360 provides comprehensive labeling and relabeling solutions for a wide range of product types and packaging formats. With hundreds of in-house die options, we can print and apply labels of nearly any size without additional tooling costs—covering everything from barcodes, cover labels, and price stickers to promotional tags, scratch-offs, UPC codes, and serialized tracking labels.

Operating from our Indianapolis location, we serve companies throughout Indiana, including Carmel, Fishers, and Columbus, with high-speed automated labeling and hand-placed application—precise down to 1/32 of an inch. We offer fast turnarounds, low minimums, and some of the most competitive pricing in the industry.

For advanced needs, our barcode serialization services include printing and scanning of unique serial numbers, Mac addresses, or SKU labels. These integrate directly into ERP and WMS systems like SAP, Oracle, or Microsoft Dynamics—providing full traceability across warehouses, third-party partners, and transit locations.

Whether you’re managing retail compliance, product tracking, or packaging rework, XPress360 ensures your labels are applied cleanly, correctly, and ready for market.

At XPress360, we specialize in assembling custom retail displays that meet exacting shipping and merchandising requirements. From simple counter displays to large, multi-part floor setups, our Indianapolis-based team builds, packs, and prepares corrugated POP displays to your specifications—with speed, accuracy, and retail readiness.

We offer both standard and turnkey services. You can send us pre-printed corrugate components and products to be kitted according to your planogram, or let us manage the full process—from design and packing to palletization and drop shipping. Every unit is secured using stretch wrap, corner boards, or strapping to ensure safe transport through the supply chain. When your retail partner receives the pallet, setup is as simple as unwrapping and placing it on the sales floor.

We also support Indiana businesses with backend logistics, including direct-to-store, distribution center, or retailer deliveries in towns like Fishers and Greenfield—so everything arrives display-ready.

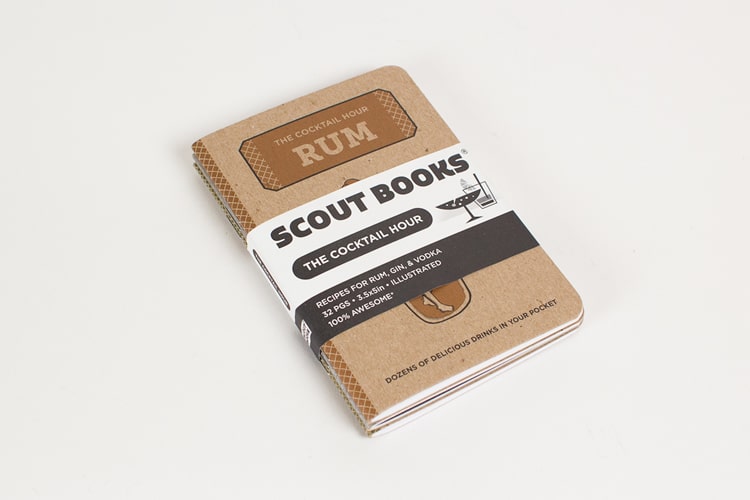

Belly bands—also known as book bands or jacket bands—are a simple, effective way to add branding, messaging, or security to your product packaging. At XPress360 in Indianapolis, we produce custom or stock belly bands using paper, SBS board, or vinyl for use on books, boxed sets, and bundled retail items.

These bands are ideal for marketing and branding. We can print logos, instructions, or promotional content directly on the band, with enhancements like foil stamping or metallic inks for added impact. They also serve functional roles in bundling grouped products—like sock packs, gift sets, or snacks—while keeping your packaging cost-efficient.

We work with brands across Indiana to pair belly bands with shrink wrap and deliver clean, secure bundled sets that reduce the need for inserts or custom boxes. Whether you want to drive repeat sales or elevate your shelf presence, our belly banding solutions are flexible, professional, and scalable.

XPress360 provides full-service fulfillment for retail, wholesale, and B2B shipments—combining product assembly, packaging, storage, and shipping in one secure, streamlined operation. Our Indianapolis-based fulfillment center serves businesses across Indiana, including Brownsburg, Plainfield, and Carmel.

We handle everything from palletized shipments and small parcel orders to LTL, FTL, and direct-to-retailer delivery. Our team is highly experienced in EDI compliance, labeling, and routing logistics, ensuring we meet the standards of national and regional distribution networks.

Clients benefit from a single partner that manages their fulfillment end-to-end. Whether you need ongoing replenishment, display-ready kits, or short-run projects, we save you time, reduce handling errors, and simplify your operations—all with real-time billing and cost transparency.

XPress360 helps Indiana brands create the perfect branded unboxing experience—combining design, printing, and assembly to take your subscription product to the next level. Whether you need custom corrugated mailers or durable shipper boxes, we offer structural packaging that protects, impresses, and performs.

From our Indianapolis hub, we serve businesses in Columbus, Fishers, and across Indiana with a full suite of design support—artwork layout, die-cut templates, CAD samples, and full proofing. Choose from standard die sizes or create a box tailored to your exact needs.

With low minimums, quick turnarounds, and flexible kitting services, we make it easy for local brands to launch, grow, or scale subscription programs.

Some packaging projects require a human touch. At XPress360, our Indianapolis-based manual assembly team handles high-detail and complex jobs—including fragile items, unusual configurations, multi-part kits, and special packaging needs.

From gluing and inspecting to precise label placement and quality checks, we ensure each piece is assembled, packed, and shipped to meet your specs. Our line-level quality controls maintain accuracy without slowing down production.

We work with companies throughout Indiana—Fishers, Greenfield, Columbus—to deliver high-quality, hand-assembled packaging that integrates seamlessly into larger fulfillment and repackaging workflows.

XPress360 specializes in fast, accurate rework and repackaging for quality assurance, retail prep, or custom shipping updates. Based in Indianapolis and serving businesses statewide, we help you minimize delays, reduce waste, and maintain quality without disrupting your production schedule.

We support a wide range of projects: carton count checks, component swaps, sorting, relabeling, shrink wrapping, visual inspections, and more. Our team can also unpack outdated packaging and rebox into new cartons to meet updated specs for Indiana retailers.

Whether your needs are in Brownsburg or Columbus, we respond quickly to repack, re-inspect, and get your products shelf-ready again.

Need a contract packaging partner that can handle both product assembly and packaging logistics? XPress360 provides turnkey co-packing solutions tailored to your production goals, from design to delivery. From our Indianapolis headquarters, we support customers across Indiana and beyond.

We manage primary and secondary packaging workflows, including bundling, labeling, retail prep, and shipping coordination. Our local vendor partnerships and in-house sourcing reduce lead times and streamline project execution. Whether you’re prepping for a statewide product rollout or local retail program, we’ve got you covered.

Our co-packing advantages include rapid quote response, scalable packaging options, fulfillment support, and full visibility across your packaging program. We help Indiana brands hit deadlines, control costs, and maintain brand integrity—without compromise.

Still Handling Assembly and Packaging In-House?

If you’re still managing your own kitting, labeling, or shrink wrapping, you’re not alone. But it’s costing you more than you think.

Many businesses lose up to 30% of production time and labor efficiency trying to manage packaging in-house. Outsourcing to a trusted contract packaging partner like XPress360 helps you reduce complexity, free up internal teams, and scale faster — without sacrificing quality or control.

Let’s talk about how we can streamline your packaging operations.

Why Do Our Customers Keep Coming Back?

Freedom

Save time and efforts by partnering with industry experts. Our years of experience give us the knowledge and skills to provide smooth, efficient processes that give you the freedom to attend to your clients and satisfy your customers.

Confidence

From maintaining quality packaging to offering innovative solutions for the changing requirements of the contract packaging industry, we promise you this: Our operations team understands the importance of doing the job right the first time.

Customization

Reach your goals with tailored solutions. Every company and project requires unique attention. That’s why XPress360 communicates with you on each project to adjust our process to fit your needs.