The choice between offset printing vs digital printing depends on the specific requirements of the project, including budget, quantity, turnaround time, and desired print quality. In this ultimate guide, we will explore each print method’s strengths and weaknesses, as understanding these can help make an informed decision based on the unique needs of the print job.

With Xpress360 digital print service you will stand out from the crowd with vibrant, unique, upscale printing and packaging solutions.

Check Out Our Services To See How We Can Bring Your Best Ideas To Life.

Offset Printing Vs Digital Printing

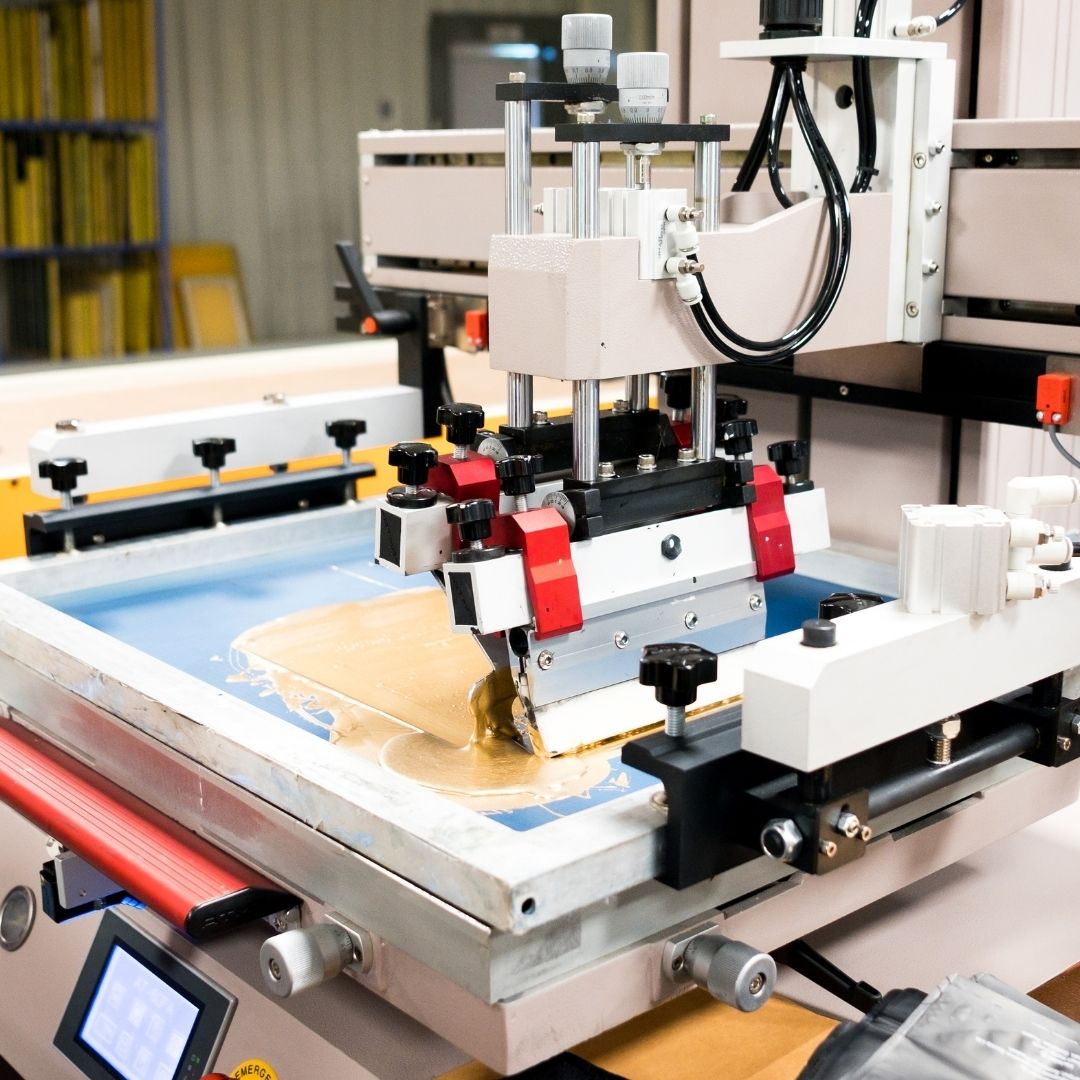

Offset printing is a traditional process that transfers inked images from a plate to a rubber sheet and then onto paper for large print runs. In contrast, digital printing requires digital-based images to print directly on paper, offering versatility for various materials and variable data. We’ll explore these printing methods even further.

Significance of Choosing the Right Printing Method

The most important factor to consider when choosing between an offset printer and a digital printer is the quantity of copies that you need to print. If you need to print a large number of copies, offset printing is usually the most cost-effective option. However, if you only need to print a small number of copies, digital printing may be a better choice.

Xpress360 utilizes digital print for short-run production and on-demand production of business cards; postcards; mailers; catalogs & booklets; brochures; presentation books; flyers; posters; letterhead; and envelopes.

Historical Evolution

The world of printing has undergone a remarkable transformation over the centuries, evolving from rudimentary hand-printing techniques to sophisticated digital methods that revolutionized the industry. Offset printing presses and digital printing stand as two pivotal advancements that have shaped the landscape of modern printing.

Origins and Development of Offset Printing

Offset printing is deeply rooted in 19th-century lithography, and was advanced with Ira W. Rubel’s 1875 innovation— the replacement of lithographic stone with a zinc plate. This change facilitated image transfer and defined offset printing. The process involves indirect ink transfer through an intermediate rubber sheet, ensuring precision and quality.

In the early 20th century, offset printing became widely used for cost-effective, high-quality mass production in newspapers, magazines, and commercial materials.

Rise and Advancements in Digital Printing

Digital printing emerged in the mid-20th century and transformed the industry by discarding physical plates for direct image transfer from digital files. Early methods, like xerography, served low-volume needs. The 1980s-1990s advancements in laser and inkjet tech elevated the quality, speed, and expansion of digital printing’s applications.

Its popularity continues to grow due to its versatility, cost-effectiveness for short runs, and customization capabilities. Digital printing is widely utilized in on-demand printing, variable data printing, and digital signage.

Impact on the Printing Industry

Offset and digital printing have transformed the printing industry by transforming the way printed materials are produced and consumed. Offset press remains dominant for high-volume, high-quality output and-quality projects, excelling in cost-effective mass production. Digital printing on the other hand has revolutionized short-run and personalized printing, offering versatility and speed for marketing materials and customized items.

The digital rise fosters the printing industry’s competition and innovation, driving advancements in quality, speed, and efficiency for both offset and digital printing.

Technology Breakdown

Both technologies have their strengths, and the decision between offset printing vs digital printing often involves finding the right balance based on the specific needs of the printing project.

Mechanism of Offset Printing

Offset printing works as a complex process that involves several steps to transfer ink from an inked image onto paper. It begins with digital image transfer to an aluminum plate, where hydrophobic and hydrophilic areas are created. Inking follows, with ink adhering to hydrophobic areas while damping repels ink from hydrophilic areas.

The inked plate transfers the image to a sheet, ensuring even distribution while the sheet transfers the image to paper under pressure. After printing, a drying process sets the image, with optional finishing steps like trimming or binding.

Technology Behind Digital Printing

Digital printing transfers digital data onto paper using liquid ink or toner. The process involves creating a digital file, processing it for compatibility and image optimization, and then transferring it to the printer’s imaging unit (utilizing technologies like lasers or inkjet technology).

The selective application of ink or toner to the printing surface to create the image comes next, followed by the finalizing with development, fixing, drying, and optional finishing steps.

Print Quality

Print quality influences both the accuracy and appearance of a print job as well as the readability, and overall impact. Both offset printing and digital printing offer high-quality results, but they differ in their specific approaches to achieving exceptional print quality.

Resolution and Detailing in Offset Printing

Offset printing produces sharp and detailed images with exceptional resolution. This is due to the precise transfer of ink from the plate to the sheet and then onto the paper. The fine dots of ink create smooth color gradients and intricate details, resulting in high-quality prints that are suitable for even the most demanding applications.

Color Accuracy in Digital Printing

However digital printing has made significant strides in color accuracy, offering vibrant and consistent colors that rival those of offset printing. Advancements in ink formulations, printhead technology, and color calibration techniques have enabled digital printers to produce remarkably accurate color representations, making them a viable choice for high-quality color printing.

Factors Influencing Print Quality

Several factors contribute to higher print quality throughout, regardless of the printing method used. These factors include:

- Image Resolution: Higher resolutions yield sharper, detailed prints.

- Paper Quality: Premium, smooth paper enhances ink adherence and vibrancy.

- Ink/Toner Quality: Quality inks/toners ensure consistent color and sharp details.

- Printer Calibration: Accurate color reproduction is maintained through proper calibration.

- Printing Environment: Controlled conditions mitigate environmental factors like humidity and dust for optimal print quality.

Xpress360 takes pride in the quality of our printed products. Combining four decades of industry expertise with clear communication ensures we not only meet but exceed your expectations.

Cost Considerations

When choosing between offset printing vs digital printing, cost is a significant factor to consider. Both methods have different cost structures and variable factors that influence the overall cost of the printing job.

Initial Setup Costs of Offset Printing

Offset printing typically involves higher initial setup costs compared to the digital printing process. This is due to the need for physical printing plates, which require specialized equipment and labor to prepare. The complexity of the plate preparation process also contributes to the higher setup costs.

Variable Costs in Digital Printing

Digital printing, in contrast, has lower initial setup costs as it does not require physical plates. The primary variable costs in digital printing are ink or toner consumption and paper costs. Other variables are print volume, image coverage, and paper selection.

Long-term Cost Efficiency Analysis

The cost-effectiveness of offset printing and digital printing depends on the specific printing needs and the length of the print run.

Offset printing is generally more cost-effective for large print runs due to the high initial setup costs being spread out over a larger number of prints. However, for small print runs, digital printing becomes more cost-effective due to its lower setup costs and variable costs per print.

Speed and Efficiency

Production speed and efficiency are crucial factors in the printing industry, influencing the ability to meet deadlines and fulfill print orders effectively. Offset printing and digital printing offer different capabilities in terms of speed and efficiency, each catering to specific printing needs.

Production Speed of Offset Printing

Offset printing is known for its ability to produce large-volume jobs efficiently. After setup, presses operate at high speeds, producing thousands of quality prints quickly. Speed is measured in impressions per minute (IPM). This makes an offset printing job ideal for high-volume projects like newspapers and magazines.

Rapid Turnaround of Digital Printing

Digital printing offers swift turnarounds for short runs and low-volume jobs. The noticeably plate-free setup minimizes preparation time and makes it ideal for last-minute, personalized, and on-demand projects. The turnaround times range from minutes to hours, with modern printers achieving speeds of up to 100 pages per minute, allowing digital print to meet time-sensitive printing needs efficiently.

Balancing Speed and Quality

The choice between offset printing and digital printing depends on the specific printing needs, balancing speed, quality, and turnaround time requirements. For high-volume, high-quality printing, offset printing remains the standard. For short-run, personalized, or time-sensitive printing, digital printing offers a balance of speed and quality.

Versatility in Printing

Both offset printing and digital printing offer versatility in material compatibility, catering to diverse printing applications.

Material Compatibility in Offset Printing

Offset Printing is known for its versatility in handling a wide range of printing materials, catering to diverse printing applications. The ability to print on various media substrates expands the creative possibilities for commercial printers and allows for unique print products.

Common materials compatible with offset printing are:

- Paper: Coated, uncoated, textured, and specialty papers.

- Cardboard: Effective for packaging, business cards, etc.

- Plastic: Enables printing on plastic for labels, signage, etc.

- Metal: Used for decorative prints, labels, and industrial applications.

- Fabric: Applicable to textiles, apparel, and promotional items.

Diverse Substrates for Digital Printing

Digital printing has also made significant strides in material compatibility, offering a growing range of substrates that can be printed on. This versatility expands the creative possibilities of digital press and allows for unique print products.

Common substrates compatible with digital printing are:

- Paper: Coated, uncoated, textured, and specialty papers.

- Cardstock: Ideal for business cards, invitations, etc.

- Vinyl: Applicable to banners, signs, and decals.

- Fabric: Techniques for textiles, apparel, and promotional items.

- Synthetic Materials: Suitable for plastic, metal, wood, and more.

Choosing Based on Print Applications

The choice between offset printing and digital printing for specific applications depends on factors such as print volume, desired quality, substrate compatibility, and turnaround time requirements. Each technology has its strengths, and understanding the versatility of each is crucial for making informed decisions in the printing industry. This is why it’s important to outsource these major decisions to a product packaging company like Xpress360.

Environmental Impact

As environmental concerns continue to grow, the printing industry is facing increasing scrutiny for its environmental impact. Both offset printing and digital printing have environmental implications, but they also offer opportunities for sustainable practices. When choosing between offset printing vs digital printing, it is important to consider the overall environmental impact, including not just the printing process itself but also the entire lifecycle of the printed product.

Sustainability in Offset Printing

Offset printing has historically been associated with a higher environmental impact due to its use of solvents, ink, and paper. However, advancements in technology and a growing focus on sustainability have led to significant improvements in offset printing’s environmental footprint.

Here are a few sustainable practices in offset printing.

- Solvent Reduction: Low-VOC solvents and solvent-less tech reduce emissions.

- Bio-based Inks: Vegetable and soy inks replace petroleum-based inks, lessening environmental impact.

- Recycled Paper: Greater use of recycled paper conserves forests and reduces deforestation.

- Waste Reduction: Practices like ink recycling and plate reclamation minimize waste generation.

Eco-Friendly Aspects of Digital Printing

Digital printing has often been touted as a more environmentally friendly alternative to offset printing due to its reduced use of chemicals and paper waste. While the digital process of printing has advantages, it is important to consider the overall environmental impact of the printing process.

Here are some eco-friendly aspects of digital printing:

- Reduced Ink Consumption: Lowers waste and environmental impact.

- Minimal Paper Waste: Direct printing from digital files minimizes paper waste.

- On-demand Printing: Reduces large print runs and minimizes unsold materials.

- Energy Efficiency: Digital printers use less energy, contributing to conservation.

Market Trends and Preferences

The printing industry is constantly evolving, adapting to changing market demands and technological advancements. Understanding current preferences and emerging trends is crucial for businesses and individuals to make informed decisions about their printing needs.

Current Industry Preferences

The printing industry is witnessing a shift towards personalization, customization, and on-demand printing. This shift is driven by increasing customer demand for unique and personalized products, as well as the growing popularity of e-commerce and digital marketing.

Emerging Trends in Printing Technologies

Technological advancements are shaping the future of the printing industry, introducing new capabilities and expanding the possibilities for printed products.

Emerging trends in printing:

- Digital Embellishment: Techniques like foil stamping and embossing enhance tactile experiences.

- 3D Printing: Expanding into customized products, packaging, and prototyping.

- Inkjet Advancements: Evolving for higher quality, speed, and broader substrate compatibility.

- Sustainable Solutions: Growing adoption of eco-friendly practices like vegetable-based inks and recycled paper.

Aligning with Market Demands

By aligning with current market preferences and embracing emerging trends, businesses and individuals can effectively utilize printing technologies to enhance their marketing efforts, product offerings, and overall brand presence. To stay ahead of the curve and meet market demands for print pieces, businesses and individuals should consider the following strategies:

- Embrace Personalization: Utilize variable data printing to create personalized marketing materials, packaging, and products.

- Incorporate Digital Printing: Leverage the versatility and speed of digital printing for short-run, on-demand, and personalized printing needs.

- Explore Digital Embellishment: Consider digital embellishment techniques to enhance the tactile appeal and uniqueness of printed products.

- Adopt Sustainable Practices: Implement sustainable printing practices to minimize environmental impact and align with growing customer preferences.

- Stay Informed: Keep abreast of emerging printing technologies and market trends to make informed decisions about printing needs.

Summary

The printing industry has undergone a significant transformation, evolving from traditional offset printing to innovative digital printing technologies. Each print method offers distinct advantages and disadvantages, and choosing between offset printing and digital printing is a critical decision for businesses and individuals.

The key to making informed choices in the printing industry lies in understanding the strengths and limitations of offset printing vs digital printing, evaluating project-specific needs, and staying attuned to technological and market trends.

Connect with us and Xpress360 will facilitate the careful consideration of your critical decision points, and optimize your printing processes for efficiency, cost-effectiveness, and environmental sustainability.

Start Your Best Product Printing Journey With A Free Quote Today!